Servo-hydraulic actuators

Actuators

The Structural Engineering Laboratory (SEL) has a large scale structural testing facility with a 3-DOF servo-hydraulic controlled test system (three MTS actuators with servo-control (two 55 kip double-rod actuators with 30 gpm servovalve, one 110 kip single-rod actuator with a 15 gpm servovalve), a 60 gpm hydraulic power supply, three 50 gpm Hydraulic service manifolds, a 4-channel servo-control system with FlexTest 60 controller and MTS test software). A 104-channel data acquisition system from Pacific Instruments (model 6005) is available for instrumentation data collection in lab and field test. Available transducers in the lab include load cells, LVDT, linear potentiometer, strain gages, thermocouples and accelerometers. A SATEC servo-hydraulic testing machine can do both tension and compression test up to 480 kips. There are also a variety of reaction frames for large scale structural testing. An overhead crane with 5 ton lift capacity is used to move test specimens around the lab.

Electronics

The hardware for real-time hybrid simulation (RTHS) consists of a dSPACE DS1103 Controller Board and a windows-based host PC. The controller board, working as a real-time controller, is fully programmable from the MATLAB Simulink block diagram environment. The board has 8 D/A channels and 20 A/D channels, all at 16-bit. Additional equipment includes: a 4-channel PCB Piezotronics signal conditioner (Model 4821C), four PCB Piezotronics accelerometers (Model 393B04), ball mill, paint disperser, ultrasonic particle de-agglomerator, paint applicators, 8-channel digital oscilloscope, oil-bath poling device, high-voltage DC power supply (up to 50 kV), HP4194A impedance analyzer, Agilent function generator, d33 meter, 16-channel NI PCI data acquisition system, digital multimeters, charge amplifiers, and many electronic accessories.

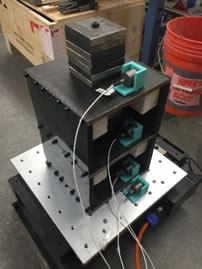

Shake table

The lab also has a small-scale uniaxial model APS 400 ELECTRO-SEIS shake table manufactured by SPEKTRA for bench-top experiments. It has a 35.6 cm 35.6 cm top plate driven by an electrodynamic vibration generator with a stroke of 15.8 cm. The shake table has a dynamic load capacity of 445 N and it can support a payload up to 23 kg. With an external controller and accelerometer, the dynamics of the shake table can be measured and used to track a desired base acceleration. A three-story steel shear building model is available for developing the require shake table RTHS algorithms. The floor sizes are 20.3 cm 20.3 cm and the height of each story is 14.0 cm. At each floor, steel blocks can be attached as additional masses. Two spring-steel columns with a thickness of 0.5 mm connect the floor plates. The spring steel ensures that the building can undergo large deformations without yielding.

Further information about the SEL can be found on the Civil and Environmental Engineering Department website.